Reliatherm: Low-cost standby battery thermal safety monitor

- Monitors individual unit temperatures for thermal runaway conditions

- Simple fail-safe change-over relay alarm interfaces (2)

- Bright LEDs pinpoint individual over-temperature jars

- Fast one-wire acid and gas-tight connections

- Sensor circuit break detection

- Alarm on power supply failure (fail-safe)

Monitor LED indications for:

- 1+ jars critical temperature

- 6+ jars critical temperature

- Power failure

- Fuse failure

- Sensor circuit break

condition within the battery cells leading to higher cell temperature, or a higher than recommended ambient

It is an exponential ‘positive feedback’ progression of increasing temperature often leading to an explosion. US IFC608.3 (2010) requires that if a sealed battery (or batteries) operated in a single premises contains over 50 gallons of acid the proprietor must install measures to prevent thermal runaway.

While US IFC608.3 is intended to prevent a catastrophic explosion damaging the surrounding environment, batteries with smaller total amounts of acid should also be protected as they are just as vulnerable to thermal runaway as larger installations.

Additionally, operating a standby battery in higher temperatures than specified can seriously shorten its life. Every 10°C above 25°C (77°F) reduces the service life of the battery by 50%.

The Reliatherm system is a dependable low-cost way of protecting your battery against over-temperature and thermal runaway conditions. Volt-free alarm relay contacts warn of critical conditions and can be used to take action to prevent the condition from continuing.

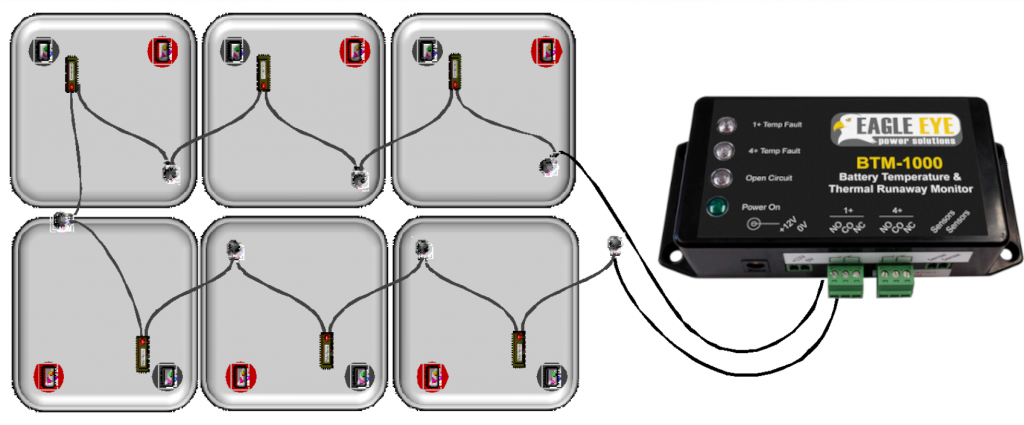

Individual sensors are quickly and securely attached to each battery jar and connected in series; the cables do not require stripping and a pair of side-cutting pliers are all that is needed to trim the cables to the required length for a neat and unobtrusive sensor installation. Interconnections typically take less than 20 seconds each.

Longer interconnections, such as shelf to shelf and rack to rack are simple to accommodate. Cable lengths, within reason, are not sensitive. Sensor installation for a 40-jar battery will typically take less than an hour.

Several batteries in the vicinity of each other may be connected in series to the same monitor. As the system is completely electrically isolated from the battery, voltages and polarities are not an issue. Sensor modules are not polarity-sensitive and may be connected either way round.

In the event of one or more jars exceeding critical temperature, or a break in the sensor circuit, the monitor warning relay activates and the Reliatherm warning LED on the monitor is illuminated; at the same time, a bright LED flashes on the sensor attached to the over-temperature battery jar, indicating the source of the fault.

Should more than 6 jars exceed critical temperature, the system-critical alarm relay activates, warning of a serious situation in the battery as a whole.

Reliatherm specification

Thermal sensor

| Activation temperature | Activation at 35°C, ± 3°C (95°F ± 5°C) |

| Environmental | Sealed IP68 |

| Module / Connections | Insulated to >2500V |

| Connection cable |

UL1007 |

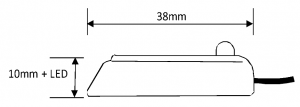

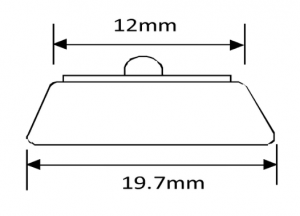

| Dimensions (L x W x D) |

38 x 20 x 10 mm |

Sensor interconnections

| Description | Gel-filled IDC ‘cold-weld’ |

| Environmental | Sealed against dirt & gasses Solvent & acid resistant |

| Module / Connections | UL listed cat 5 |

| Interconnection strength |

>90% of wire breaking strength |

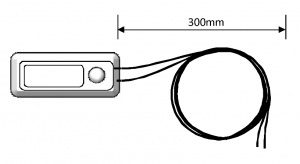

| Dimensions (L) |

300 mm |

Monitor

| Fixture | DIN rail mounted |

| Input Voltage |

DC 12V 2-pin connectors or 12V AC/DC wall adapter @ 0.1A |

| Input Voltage | DC 12V 2-pin connectors or 12V AC/DC wall adapter |

| Output Relays | (2) SPDT volt-free contact relays Output relay contact ratings: 7A at 240 VAC, 10A at 120 VAC

|

| Dimensions (L x W x D) | 84 x 40 x 77 mm |

| Compliance | IFC 2015 – 608.3, NFPA 1 – Article 53.3.2 |